From Gears to Idlers: The Full Option for Trusted Undercarriage Parts

From Gears to Idlers: The Full Option for Trusted Undercarriage Parts

Blog Article

Maximize Efficiency With Sturdy Undercarriage Parts

In the world of heavy machinery and tools, the duty of undercarriage parts is vital in ensuring optimal performance and longevity. The performance and efficiency of these elements can significantly affect the total procedure of equipment, making the selection of sturdy undercarriage components a vital decision for operators and managers alike. By exploring the intricate relationship in between resilience and performance in undercarriage parts, a much deeper understanding of the subject emerges, clarifying the crucial aspects that drive functional success. As we navigate with the intricacies of undercarriage durability, upkeep, and part option, a thorough expedition waits for to reveal the key techniques for achieving peak performance in sturdy applications.

Benefits of Making Use Of Durable Undercarriage Components

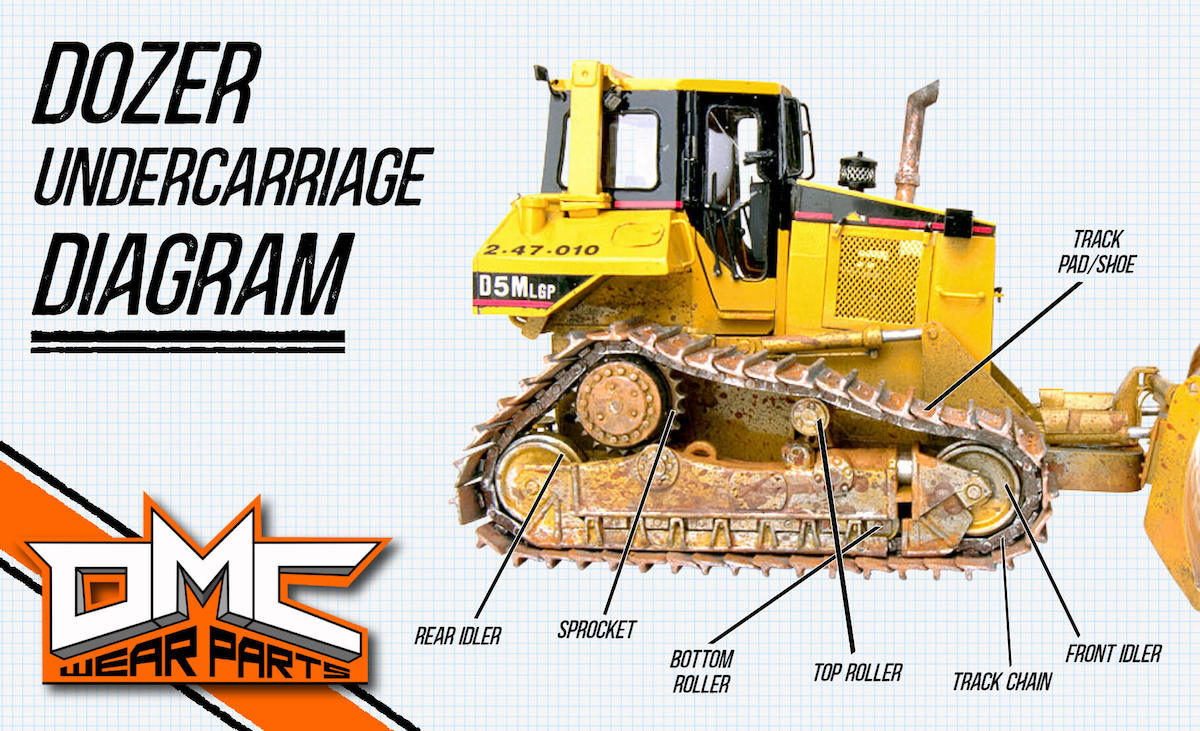

Making use of durable undercarriage parts not only improves the long life of hefty equipment but also reduces upkeep prices dramatically. By buying top quality undercarriage components, such as tracks, idlers, rollers, and gears, equipment drivers can experience raised uptime and enhanced total performance.

Moreover, the longevity of hefty equipment is directly connected to the top quality of its undercarriage parts. Long lasting elements can withstand the rigors of requiring applications, making sure that the equipment stays functional for prolonged periods. As an outcome, drivers can avoid pricey downtime and maintenance costs, eventually taking full advantage of the return on financial investment for their equipment.

Aspects Impacting Undercarriage Resilience

The longevity of undercarriage components in heavy equipment is influenced by various critical elements that directly effect performance and longevity. High-grade materials, such as hardened steel, are necessary for standing up to the extreme problems and heavy loads that undercarriage components are subjected to - undercarriage parts.

Furthermore, ecological aspects can have a significant influence on the durability of undercarriage parts. Direct exposure to abrasive products, severe temperatures, and harsh working problems can speed up wear and tear on undercarriage parts. Picking undercarriage parts that are especially designed to stand up to these environmental challenges is crucial for ensuring durability.

Furthermore, the style and design of undercarriage parts have a direct influence on their resilience. Parts that are created to distribute lots equally, lower friction, and minimize tension concentrations are more probable to have a longer life expectancy - undercarriage parts. By taking into consideration these critical factors, equipment operators can make best use of the durability and efficiency of their undercarriage elements

Maintenance Tips for Prolonging Undercarriage Life

Executing regular maintenance routines is essential for extending the life-span of undercarriage components in heavy equipment. To lengthen the undercarriage life, it is critical to regularly evaluate for deterioration. On a regular basis look for loosened or missing screws, damaged rollers, or misaligned tracks, as these issues can rise and create additional damages otherwise attended to quickly. Additionally, ensure that the undercarriage is properly oiled according to maker guidelines to decrease friction and protect against early wear.

An additional crucial maintenance idea is to keep the undercarriage tidy from dirt, rocks, and particles. Buildup in the undercarriage can increase wear and corrosion, bring about expensive fixings. Washing the undercarriage after procedure in harsh problems is suggested to stop these problems.

Last but not least, tracking and recording upkeep activities can help in producing a proactive maintenance timetable. Keeping in-depth documents of examinations, replacements, and repair services can give valuable insights into the undercarriage's condition and efficiency over time, helping in forecasting and preventing potential failures. By complying with these upkeep tips carefully, operators can considerably boost the resilience and performance of undercarriage parts in heavy machinery.

Choosing the Right Undercarriage Parts

Picking proper undercarriage components link is crucial for making the most of the efficiency and long life of heavy equipment. When it comes to selecting the right undercarriage parts, there are several variables to think about.

Choosing for trustworthy brand names known for producing high-performance and long lasting undercarriage components can dramatically influence the overall effectiveness and durability of the machinery. By thoroughly choosing the best undercarriage parts, tools proprietors can boost performance, lower downtime, and expand the life-span of their hefty equipment.

Study: Enhanced Performance With Sturdy Parts

Incorporating long lasting undercarriage parts has actually demonstrated significant improvements in machinery efficiency. One study included a construction firm that upgraded its excavator's undercarriage parts to much more sturdy choices. The firm observed a significant decrease in downtime because of undercarriage upkeep, leading to increased efficiency and price savings. The long lasting parts stood up to harsh working conditions, reducing deterioration dramatically.

In another instance, a mining operation changed the undercarriage components of its excavator with top quality, long lasting options. This switch resulted in a remarkable enhancement in the bulldozer's ability to move and total efficiency. The machine can navigate challenging terrains much more effectively, bring about boosted functional efficiency and reduced fuel intake.

Additionally, a logging company invested in resilient undercarriage parts for its forestry devices. The upgraded elements displayed extended life expectancy and raised resistance to abrasion from rough surface. The company experienced reduced maintenance costs and better tools uptime, inevitably improving its bottom line. These study emphasize the substantial advantages of utilizing resilient undercarriage parts in maximizing equipment efficiency and durability.

Final Thought

Finally, making use of long lasting undercarriage parts can significantly boost efficiency and long life of heavy equipment. Factors such as correct maintenance and picking the ideal components play an essential duty in optimizing undercarriage toughness. By executing these strategies, services can reduce downtime, rise efficiency, and eventually reduce functional prices. Study have revealed that buying resilient Read More Here undercarriage components can result in boosted overall efficiency and productivity in numerous sectors.

The performance and performance of these components can considerably affect the total procedure of equipment, making the choice of long lasting undercarriage components an important choice for supervisors and drivers alike.Incorporating resilient her latest blog undercarriage parts has shown substantial improvements in equipment efficiency. These case studies highlight the concrete benefits of utilizing long lasting undercarriage components in maximizing equipment efficiency and long life.

In verdict, making use of sturdy undercarriage components can dramatically improve performance and long life of heavy machinery (undercarriage parts). Case studies have shown that investing in durable undercarriage parts can lead to boosted total efficiency and productivity in different markets

Report this page